CUSTOM AUTOMATION ASSEMBLY

Machinery

SMT Industries Incorporated is a company that has been specializing in custom-built assembly machines for 47 years. Each machine is custom designed by our experienced engineering department and built to meet the specifications of our customers. SMT can start with a print and build to suit production requirements and customer machine specifications.

Prototype Assembly

Call SMT for prototype assembly as well as low and high volume assembly. SMT can machine prototype tooling in house for speedy turnaround for your customer’s demanding needs. We have a large fabrication department, supported by outstanding engineering and experienced fabrication / assembly technicians.

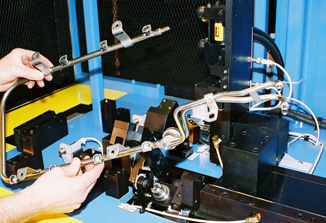

Manual Assembly Fixtures

SMT can also provide you with high quality manual assembly fixtures. Designed, fabricated and build in house!

Automotive Industry Fuel Cups

SMT designed this machine to assemble cups to fuel tubes for the automotive industry. The first machine station pressed two fuel tubes into a pre-assembled cup. After the tubes were pressed to specification, the machine welded a cross bracket as well as a mounting bracket to the tube / cup assembly. SMT Industries utilized high frequency DC welding for bracket fastening. Our welding system can weld thin wall stainless materials with very strong pre-braze welds and no discoloration!

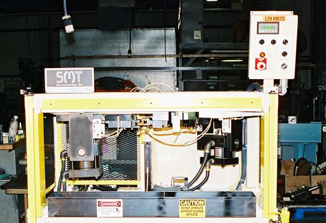

Inlet Assembly

Here is another high volume automotive assembly machine. SMT designed and built this machine to assemble a block to an inlet assembly to an inlet tube. This machine did the bending of the inlet tube as well. SMT Industries will completely automate the system if your EAV’s require. Load the tubes and blocks into hopper, press cycle start and walk away!

Fuel Rail Assembly

SMT designed a machine to assemble and inlet assembly to a main fuel rail for the automotive industry. The first machine station pressed the inlet / outlet tube assembly into the main fuel rail. SMT Industries also built the cup assembly equipment as well as a restrike machine that tweaked the entire fuel rail assembly to specification after the braze operation!

Flange Assembly

SMT designed and built this automotive assembly machine to crimp tubes into a fuel sending flange assembly. SMT Industries also designed and built the flange welding machine. The welding criterion was very demanding, but easily done with SMT Industries engineering and component selections.

Truck Motor Assembly

SMT designed and built a machine to press a piston cooler tube into a mounting flange. This machine also bent the tube after the braze operation, which was put through an automatic target and pressure test. This part had to spray liquid and hit a target 13 inches away within a .375 inch target hole, as well as meet the specified pressure. The part sprays the hot spot on the bottom side of a diesel motor piston. Also, we incorporated an additional leak testing station (pre bend) to check the braze.

Appliance Component Assembly

SMT designed and built this machine to press a rivet into the stove hinge assembly. The rivet is automatically fed into a ram unit and opened up on the opposite side. A vibratory bowl fed the rivets to the assembly. Super fast cycle for demanding production numbers.

Injector Cup Assembly

SMT designed and built this machine to stake all four injector cups into both the right and left hand main fuel rails. Solid holding until the assembly was brazed.

Dual Torque Gun Assembly

SMT designed and built this machine to attach an fuel sensing unit to a bracket that is welded to a fuel rail. The torque gun system monitored the torque, watching for the correct criteria. It the proper criteria was not met, the machine would hold the rejected part until a fail tag was placed on the part.